Throughout our history, American Tool has been at the forefront of the industry, creating better tools in a better way. Newell's strength allows them to concentrate on their business and on innovation more than ever. And today, as a part of Newell Rubbermaid, they enjoy the financial backing and systems support of a $7 billion global consumer products company. For more than 75 years, it's been an idea that has permeated the culture of their company and continues to drive everything they do. Compare router table.Innovation is a mainstay of American Tool. Cross vises, which can be adjusted using leadscrews in the X and Y axes these are useful if many holes need to be drilled in the same workpiece using a drill press.They allow speed and precision in the placement of the work. compound slide vises are more complex machine vises.

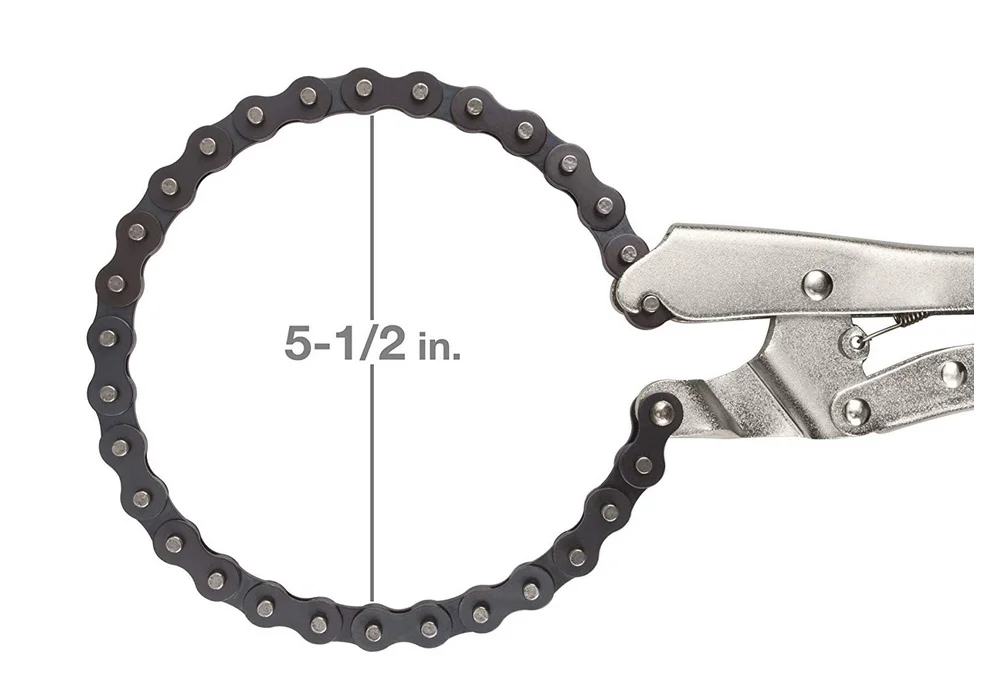

Some vises have a rotating design to provide both bench and pipe jaws. Vises that combine the functions of a pipe vise with a metalworker's vise do exist, and are quite common. They also help to secure an object while working on the object. Some unique vises combine these features in a rotating design. They usually have smooth jaws for wood, plastic and light metalworking, but some have serrated jaws for getting a better grip on metal. The yoke type vise uses a screw to clamp down the pipe, and the chain style uses a chain for securing the pipe.Ĭlamp-on vises are basically very light-duty bench vises. There are two main styles: chain and yoke. Pipe vises are a plumber's tool, often used to hold pipes in place for threading and cutting. Jewelers also use vacuum vises to hold jewelry. They are mounted with a suction cup and often have an articulated joint in the middle to allow the vise to pivot and swivel. Some hobbyists use a machine vise as a bench vise because of the low cost and small size.Ī vacuum vise is a hobbyist's tool, commonly used to hold circuit boards, model airplanes and other small work. Abrasive chop saws have a special type of machine vise built into the saw. Machine vises are mounted on drill presses, grinding machines and milling machines.

Most homeowner's bench vises have an exposed screw. Some engineer's vises marketed as "Homeowner Grade" are not made of steel or cast iron, but of pot metal or a very low grade of iron, typically with a tensile strength of under 10 ksi. Most engineer's vises have a swivel base. The vise may include other features such as a small anvil on the back of its body. The jaw opening of an engineer's vise is almost always the same size as the jaw width, if not bigger.Īn engineer's vise is bolted onto the top surface of a workbench, with the face of the fixed jaws just forward of its front edge. Soft jaw covers made of aluminum, copper, wood (for woodworking) or plastic may be used to protect delicate work. The jaws are often separate and replaceable, usually engraved with serrated or diamond teeth. Cast iron is popular because it is typically 30 ksi grey iron which is rigid, strong and inexpensive. Some vies have a cast iron body but a steel channel bar. However, most heavy duty vises are 55,000 psi cast steel or 65,000 psi ductile iron. It is sometimes made of cast steel or malleable cast iron, but most are made of cast iron. It is used to hold metal when filing or cutting. One common variety of face vise is the leg vise, which has a long extension down to the floor, with a provision to adjust the spacing of the bottom of the leg, to keep the clamping surfaces of the jaws approximately parallel, even though the work to be clamped may be of various thicknesses.Īn engineer's vise, also known as a metalworking vise or machinist's vise, is used to clamp metal instead of wood. Traditional workbench vises are commonly either face vises, attached to the front of the workbench, near the left end (for a right-handed worker) or end vises, attached to or forming part of the right end of the bench.

Common thread types are Acme and buttress. When disengaged the movable jaw may be moved in or out throughout its entire range of motion, vastly speeding up the process of adjustment. "Quick-release" vises employ a split nut that allows the screw to engage or disengage with a half-turn of the handle. The movable jaw may include a retractable dog to hold work against a bench dog. Their jaws are made of wood or metal, the latter usually faced with wood, called cheeks, to avoid marring the work. Woodworking vises are attached to a workbench, typically flush with its work surface.

0 kommentar(er)

0 kommentar(er)